Mycelium: Smart Fleet Management System for Intelligent Automation

Robotic companies increasingly focus on fleet management software: its interface, design, functionality and usability.

Fleet management system is responsible for centralizing the flow of the robot fleet, allowing operators to act from several standard communication devices: tablets, computers or mobile phones. This allows easy access and real-time visualization anytime from anywhere.

Modern fleet management systems can control hundreds of robots and play a key role in performing complex operations and precise functionalities.

It is undoubtedly essential to provide users with a tool that is intuitive, easy to understand and easy to use.

Meet Mycelium: iFollow’s Fleet Management Software

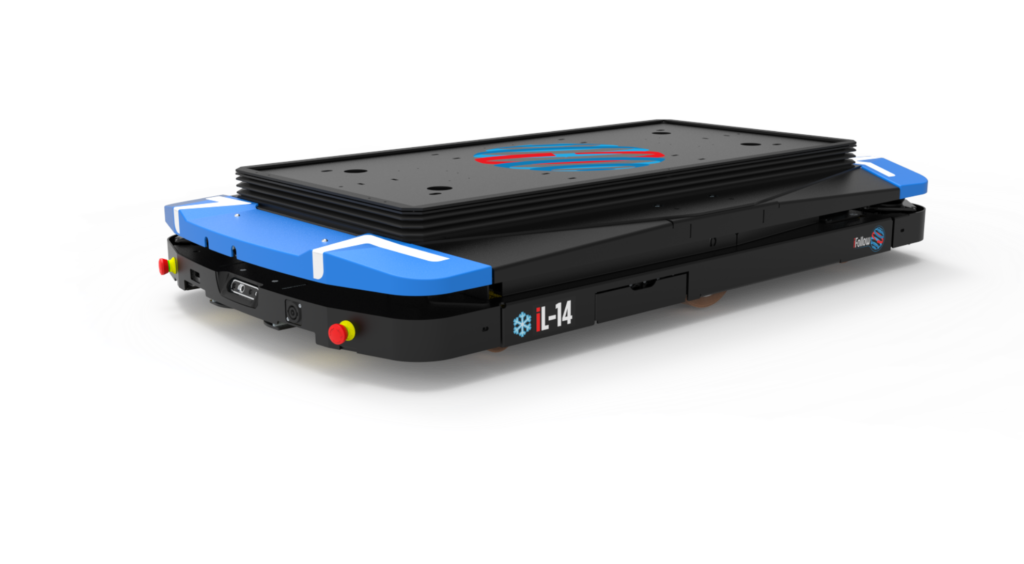

At iFollow, we have created Mycelium – a user-friendly fleet management software for organizing a fleet of mobile robots and real-time visualization of picking and in-and-out transport missions.

The software supports up to 200 robots and is easy to install and use on different devices.

Once installed, users can view all workflows in a single dashboard and manage missions and robot positions without any programming knowledge. They can also modify the tasks and their order with just a few clicks.

Mycelium offers data-rich statistics of operations for desired periods.

Functional and Data-rich Software for Operational Excellence

What exactly will you get with Mycelium?

iFollow’s fleet management system allows the following:

The software's speed, simplicity, intelligence and effectiveness ensure optimized collision-free path planning, configuration and easy operation via a web user interface.

The software's speed, simplicity, intelligence and effectiveness ensure optimized collision-free path planning, configuration and easy operation via a web user interface.

Optimizer and Supervisor: Different Roles for a Common Good

Mycelium’s optimizer is responsible for data gathering and transfer while the supervisor monitors the processes.

Optimizer responds to the robot’s local optimization; for example, it can choose the most optimal route. It is also equipped with all the intelligence to gather and interpret relevant data received from client sever such as real-time changes, planning data, the configuration of parameters, etc.

Later this information is converted into actions and a fleet of iFollow’s autonomous mobile robots start performing them in the right order.

The supervisor gives you a user-friendly view of all the workflows and traceability.

You will have a detailed view of your facility and the robot's actions.