Challenges in Cold Chain Storages

Labor and energy represent the two highest costs in cold chain warehouses.

Energy Costs in Cold Chain Warehousing Remain High

Labor shortages in cold storage – as much of a challenge as costs

Flexible AMR for Cold Chain Warehouses

Autonomous Navigation

iFollow cold chain AMR does not modify the given warehouse during deployment. It has the necessary equipment for autonomous navigation, offering a level of safety far superior to human handling.

Stereoscopic camera

Equipped with security cameras and lidars, the AMR robot has 360° vision and can travel on complex routes that are very narrow and has a perfect perception of the environment.

Management of intralogistics flows

The flexibility of maneuvering around people and obstacles without guidance, safety, and non-stop performance are just a few reasons why this logistics solution is attractive to cold chain storage warehousing businesses.

Higher market demand, further pressure on productivity

The labor attraction to the cold chain facilities is not growing, but the market does. The global cold storage market size was valued at USD 138.97 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 17.2% from 2023 to 2030.

Peak seasonal demands make it even more difficult to cope with efficiency, productivity and capacity.

A question arises – how to optimize and keep the supply chain in cold chain warehousing scalable and sustainable?

Autonomous mobile robots for logistics in cold storage warehousing

Technological advances such as automated transport in cold storages can help achieve these objectives and keep energy costs down. Also, as distribution centers continue to grow vertically, automation is not a question of luxury but an ultimate need.

In fact, it represents the only viable solution to optimize throughput, labor and energy management.

Automation systems require some particular adaptations to perform reliably in low-temperature environments.

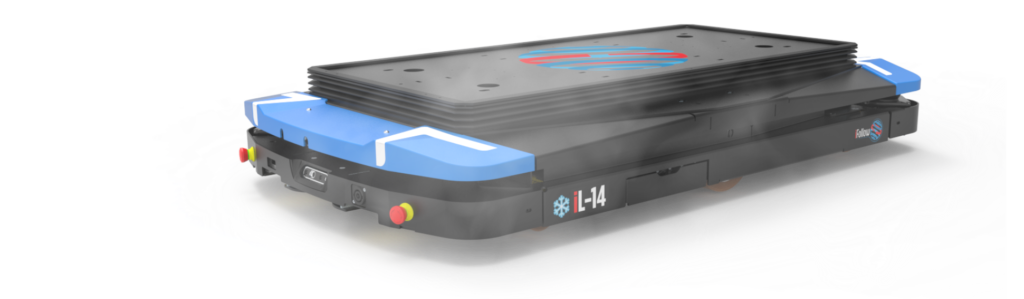

iFollow designed a collaborative mobile robot to transport roll cages and pallets in cold storages. The AMR serves as the operator’s right-hand assistant in picking operations and order preparation and handles internal transport moving.

This autonomous mobile robot is robust and sophisticated enough to bear intense temperatures and also smoothly transit from cold to ambient environments.

Autonomous Mobile Robots for Data-Driven Operations

Today’s warehouse management systems integrate technologies in a single platform while offering standard interfaces to ERP and other software systems.

This aims to provide new insight into equipment availability and performance while also enabling new capabilities, such as visualization.

Mobile robots help cold chains become more data-driven.

Therefore, iFollow strongly focuses on fleet management software to provide maximum data on robot operations.

It is vital to provide users with a tool that is easy to understand and easy to use. The fleet management software – Mycelium can be easily integrated into ERP. It offers an intuitive interface design, functionality and usability.

Especially cold chain warehouses need remote visibility of critical logistics operations in a deep freeze environment. This will help increase visibility into operations, improve coordination across systems, and adapt to changes in real-time.