MOBILE ROBOT SOLUTIONS

AMR Robots

for Logistics and Industry

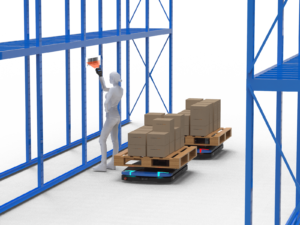

Achieve maximum productivity, safety and accuracy in warehouse operations with autonomous mobile robots (AMRs)

Handling logistics workflows in an intelligent and modern way is an essential component of supply chain management that strategically impacts your business. Warehouse automation with autonomous mobile robots (AMRs) has solved some major issues related to productivity, traceability and labor shortage, to name a few.

Explore our AMRs

Explore our AMRs

iFollow AMRs are compact and ideal for ergonomics, only 17cm high, which is approximately half-size of other AMRs. Our product range includes four robots that transport from 300kg to 1,2t.

Meet iL300 kg, iL600 kg, iL1000 kg & iL1200 kg and choose the one that suits your automation needs best.

iFollow has a range of AMRs for cold chain. They operate down to -25°C and move from a negative environment to a positive without condensation.

iFollow robots are 100% customizable to your needs.

How and where iFollow’s AMR robots work ?

How and where iFollow’s AMR robots work ?

iFollow AMRs navigate fully autonomously. Unlike AGVs, AMRs don’t need tapes, reflectors, QR codes, or any other guidance to maneuver in your warehouse environment safely. AMR uses wide-angle stereoscopic front and back cameras and a long-distance LIDAR scanner for a 360° degree field of vision.

Our AMRs automate intralogistics for industry and logistics. Automotive, logistics and 3PL, retail, FMCG, pharmaceutical, and aviation are few of the many activity sectors we cover. You can see different applications at clients’ premises in these videos.

They trust us

Mobile robots are your reliable partners in warehouse automation operations

Mobile robots are your reliable partners in warehouse automation operations

Autonomous mobile robots for intralogistics automation

Employees are not motivated by mundane, monotonous tasks, especially when this has a direct negative impact on their health – increasing disorder risk on their musculoskeletal system. You can overcome multiple challenges related to employee safety, labor shortage and high turnover rate with AMRs.

Let mobile robots handle routine and heavy-duty tasks such as the autonomous transport of large loads on pallets, roll cages, conveyors and other top modules.

iFollow’s autonomous mobile robots automate internal transport flows; mobile robots operate smoothly in different logistics scenarios, whether inbound logistics, A-B moving missions or outbound transport.

Thanks to a compact design, transportation through narrow corridors is not an issue for our AMR robots. They can also move loads in challenging environments, full of machinery and even on imperfect floors.

In tramming operations, our robots increase productivity up to 50% and deliver fast ROI – between 12 and 24 months.

Autonomous mobile robots for picking

In picking operations, iFollow’s autonomous mobile robots serve as the operator’s right-hand assistant.

They smoothly collaborate with pickers, automating order picking and guaranteeing increased productivity, traceability and operational excellence.

Human-AMR collaboration significantly decreases error rates and minimizes the operator’s walking time.

Some of the significant advantages of robot-human collaboration are:

- Autonomous order-picking increases the operational efficiency of the warehouse

- Employees operate in better conditions, as they don’t have to walk long distances pushing and pulling the payload. Thus, AMRs reduce musculoskeletal disorder risk.

- Robots are operational 24/7, delivering non-stop performance and boosting productivity

Our sectors of ACTIVITY

Our sectors of ACTIVITY

Learn how iFollow automation solutions fit multiple industries.

OUR SOFTWARE MYCELIUM

OUR SOFTWARE MYCELIUM

Mycelium – iFollow’s intuitive and user-friendly fleet manager is easy to install and use on all devices: laptops or mobile. It supports up to 200 robots.

Once installed, you can manage the robots’ mission and orders without programming skills. You can also modify tasks and their order within just a few clicks.

Mycelium allows

– Smooth communication between robots: the mobile robots are interlinked so that they can share useful information with each other.

– Finding and optimizing the best route for the entire fleet of AMRs.

– Obstacle avoidance technology in a dynamic environment, full of people and machinery or any other static or dynamic obstacle

– Real-time fleet monitoring and visualization of your warehouse activity.

Want to know more? Book a call with us.

Track the status of your fleet in real time

Keep an eye on every step of the

robotic process

Passionate about autonomous mobile robots?

Join our team!

We are hiring skilled and committed people, able to communicate efficiently through different teams.

Teamwork and a shared common vision are important parts of our culture. Thanks to these factors, we grew from an ambitious startup founded in 2017 to a fast-growing scale-up.

Today, we manufacture fleets of robots and fully develop our own navigation and fleet management algorithms. We grew from a small company to almost 100 people in different teams: R and D, engineering, commissioning, commercial, marketing, service and customer satisfaction teams.

Our robots operate in multiple industries globally: food & beverage, industrial, pharmaceutical, chemical, cosmetic, logistics and mass distribution sectors.

We are proud of this growth and the more is yet to come! Exciting to be part of iFollow team?

Join us now!

We are proud of this growth and the best is yet to come!

Want to be part of the iFollow team?